ON-BOARD MACHINE

SUCTION HOODS

Suction Hoods on the Web

Positioned at points where dust is generated; they are designed to remove the largest amount during line operation. The hoods are placed at specific points and can be easily repositioned; they are made of painted galvanized steel.

Floor Hoods

Positioned to intercept as much dust as possible, they come into action during reel changes or any other phase in which the machine is stopped. At the operator’s discretion, they can also be activated during normal line operation and operate in combination with the cleaning system working on the web.

Blowing tubes made of stainless steel featuring blowing nozzles that ensure the generated dust remains suspended, allowing the suction hoods to remove it.

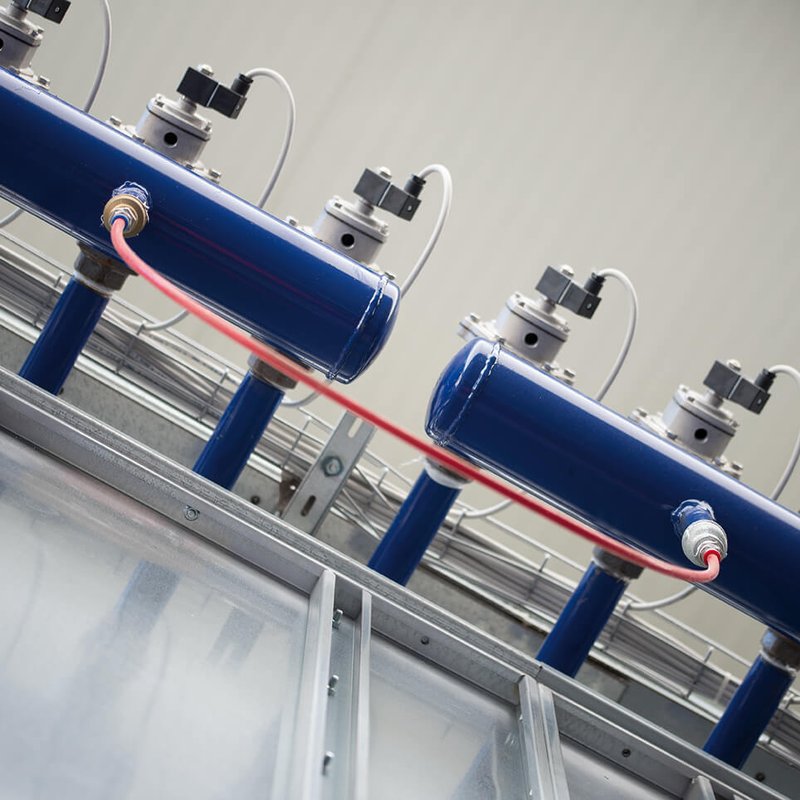

The blowers are equipped with pneumatic valves positioned at the head of the piping, which can be individually activated by a bank of solenoid valves housed outside the line’s casing and programmable through the operator panel.

The careful design of this system eliminates the risk of fire due to the presence of electronic components in the area of highest dust contamination.

Tecnoimpianti offers cleaning systems capable of autonomously managing the cleaning of the plant while preserving the lifespan of the filtering elements. The devices and the integrated electronic system constitute a complete solution for efficient management and automation of dust removal systems.

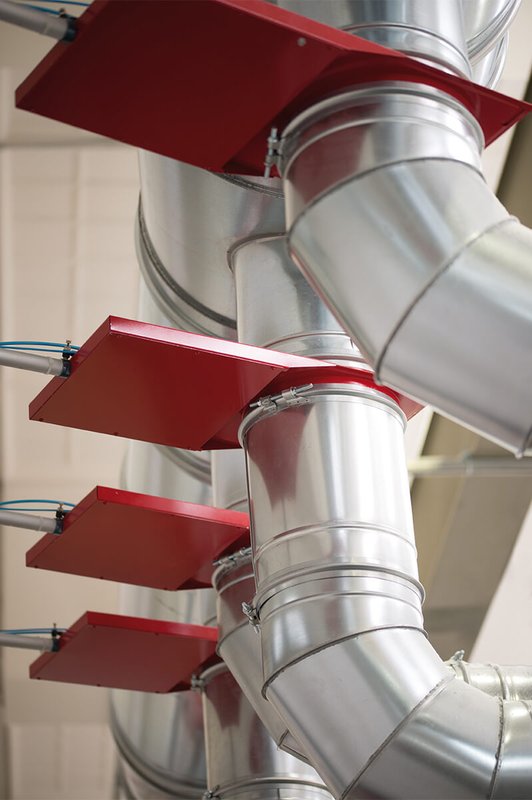

Through its own technical office, Tecnoimpianti designs and manufactures all the piping that connects the various parts of the plant.

Should clients request it, Tecnoimpianti can provide the detailed piping design for on-site construction.

Dry separators with filters constructed of galvanized steel, equipped with several filtering bags made of antistatic needle-punched polyester felt with a diameter of 150 mm. They are anchored to a rigid metal structure with anchoring sleeves.The filter is equipped with a compressed air manifold with solenoid valves and a solenoid operated by an electronic control unit that activates and deactivates at variable frequencies.The lower part of the filter features a hopper, screw conveyor, and rotary valve for dust discharge.

Tecnoimpianti designs and supplies suitable fans with reinforced structures—reliability and durability for heavy-duty applications and harsh environments. Specific construction technologies guarantee a long lifespan even in continuous cycles.

Low and medium-pressure fans, centrifugal industrial fans provide a continuous and regular airflow for many applications, even at high flow rates.