REMOVAL AND

SHREDDING OF WASTE

Robust and efficient industrial counter-rotating shaft shredders, designed for effective performance in processes that require volumetric reduction and rough shaping of materials, with partial control over the output size.

The shredders can be used for the treatment and processing of any type of solid waste.

They are designed to achieve high torque at low rotation speeds and consequently have very low energy consumption. The shredder blades, made of special steels, ensure long life cycles and significant energy savings.

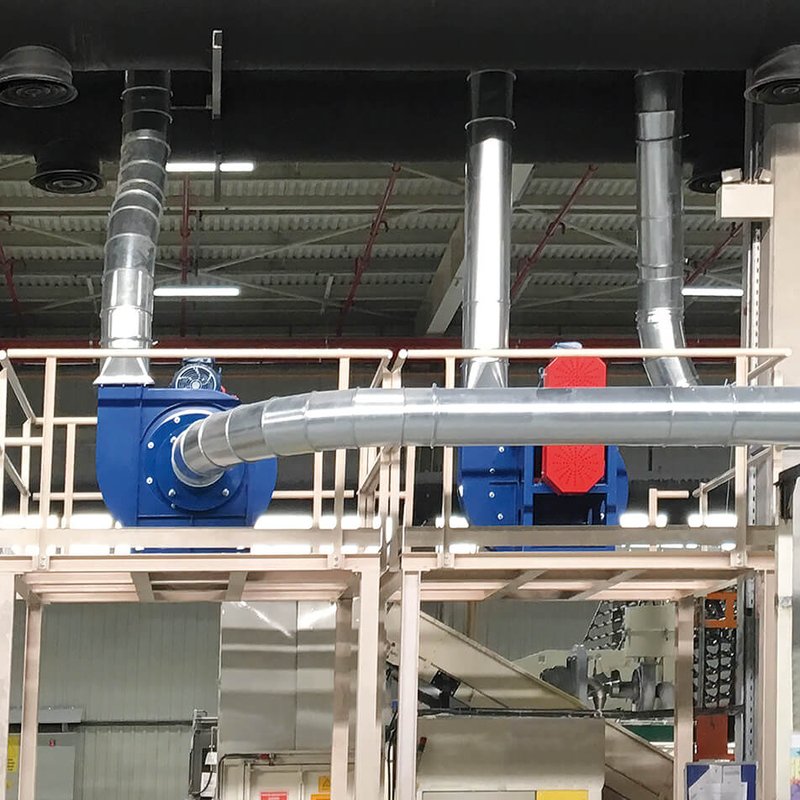

This line of fans is suitable for the suction of very dusty air with suspended materials (dust or granulates). The open radial impellers allow the passage of even filamentous materials and are ideal for all applications where a normal impeller could clog.

This line of fans can operate in Scrap Shredding mode (Shredding Suction). Appropriately shaped blades applied to the impeller and/or the inlet cut the paper material transported in the fluid.

The static separator is a device designed and engineered for the separation of paper waste. Built in a wide range of models, it can meet all required production needs.

Its simplicity of operation makes it reliable and maintenance-free compared to traditional rotary or cyclone separators, allowing for easy application even in the tightest spaces.

The reduced pressure losses also ensure energy savings in the sizing of transport systems.

Hydraulic compaction presses are designed for the volumetric reduction and packaging of paper and cardboard. The use of advanced technology and integration with the trim treatment plant allows us to meet any type of need by offering greater material loading capacity. The work cycle is completely automatic and can be managed directly from the trim treatment system.